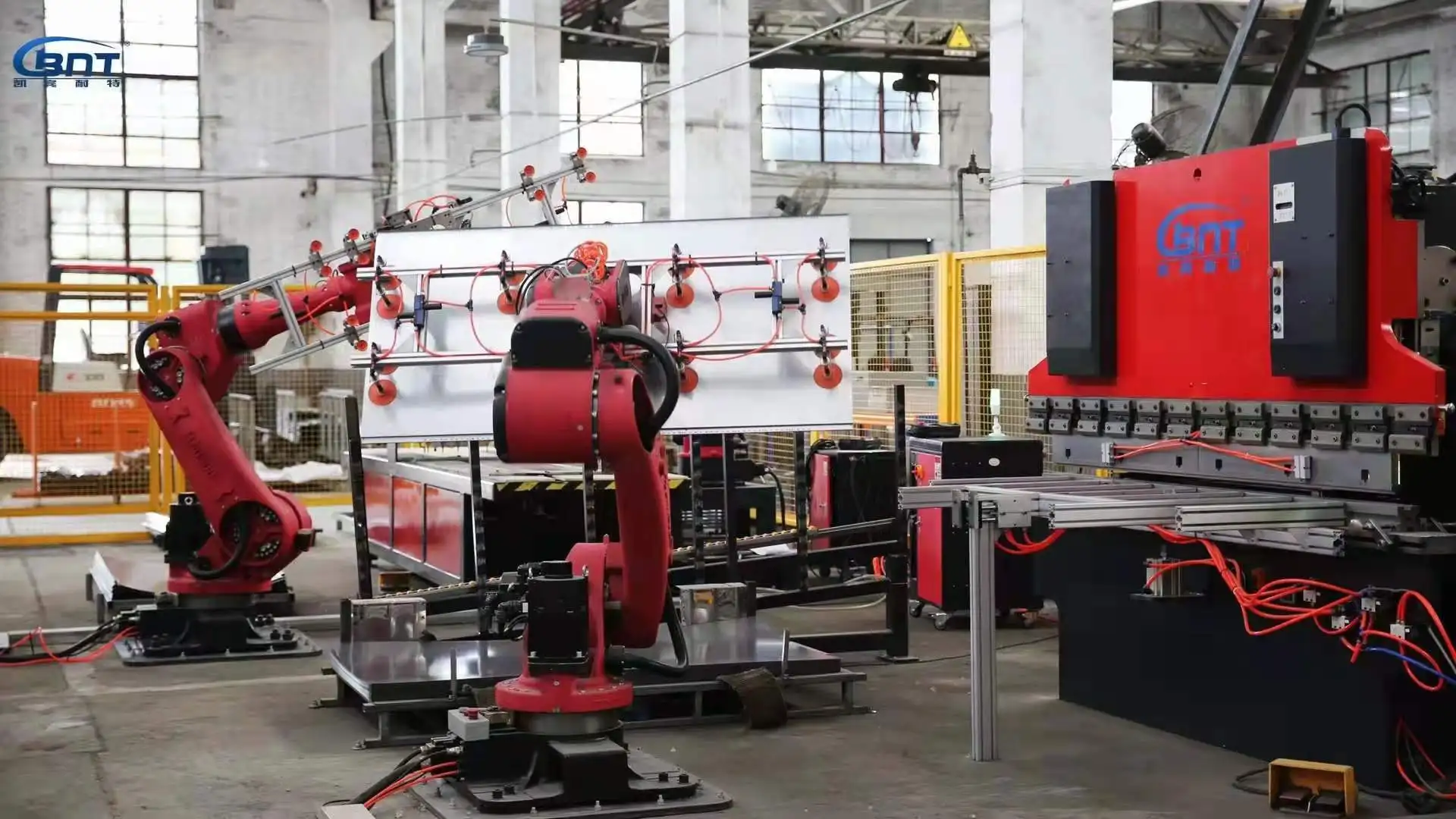

Shelf Automatic Production Line For Metal Cabinet

1. Specification

No. | Equipment name | Brand | Size | Amount | Function |

1 | Double ends of short edge bending machine | CBNT, ODM&OEM | 1850*2220*1950mm | 1 | Double ends bending |

2 | Double ends of long edge bending machine | 1650*2300*1650mm | 1 | Double ends bending |

3 | Uncoiler | | 1 | Uncoil |

4 | Leveler/Flatting machine | | 1 | Correction leveling/ Flatting |

5 | Welding line | | 1 | spot welding, dot welding; |

6 | Truss robot | | 1 | Unloading and Stacking |

7 | Truss robot | | 1 | Reinforce-bar loading |

8 | Hand cart (reinforce-bar) | | 2 | Put the reinforce-bar for using |

9 | Operating system | | 1 | |

10 | Power | | 80KW | | |

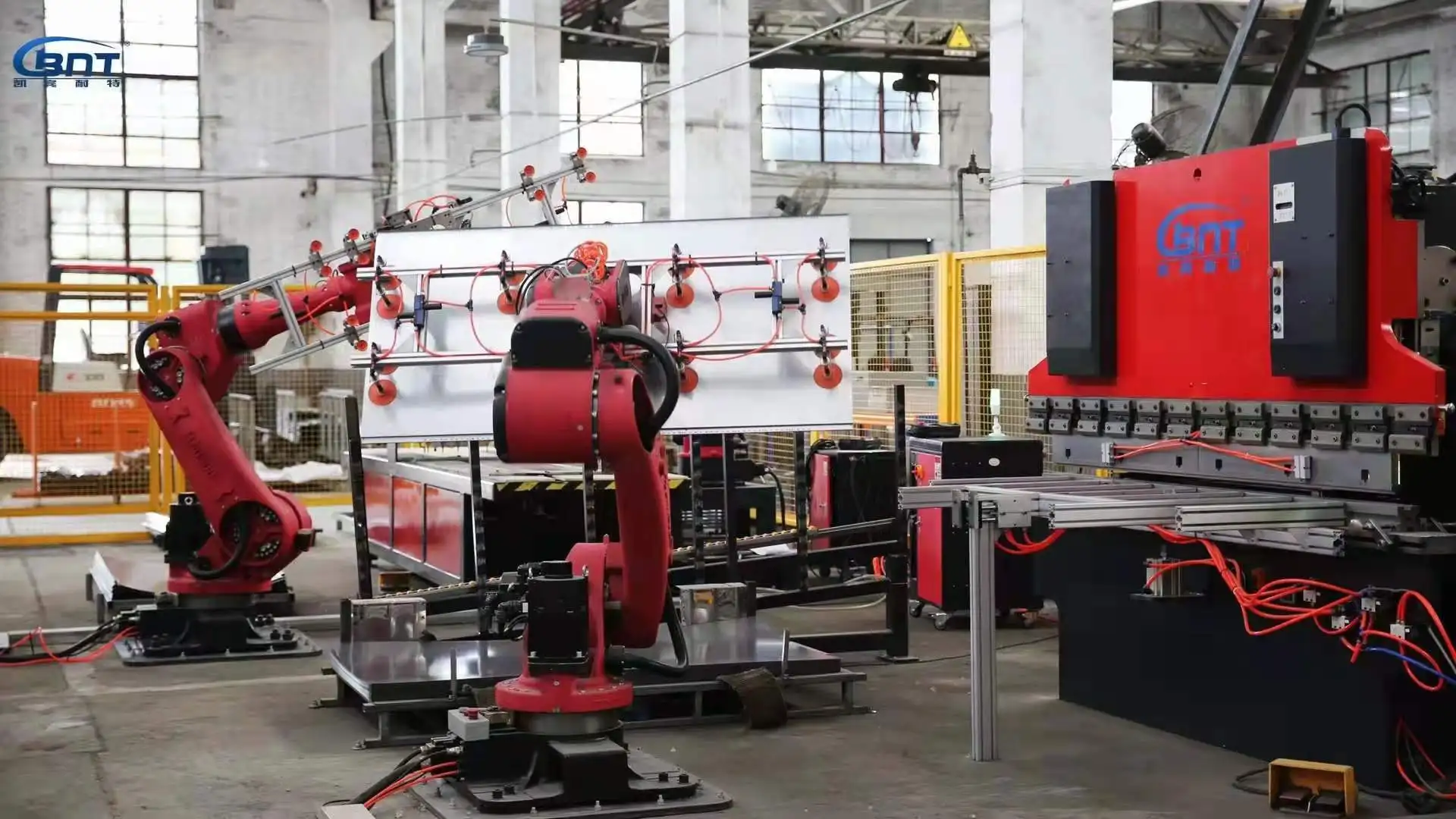

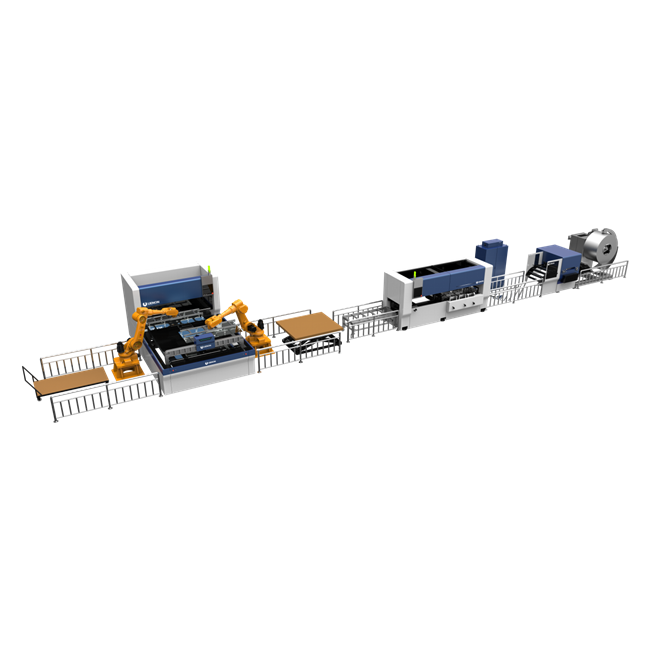

Selecting our shelf boards automatic bending and spot welding production line, the cutting plate can be bent at both ends of the short side of the plate through the double end bending center, then through the long sides of the bending center of the plate, which can bend multiple times at the same time. Through the conveyor rack to the welding line, and completes the reinforcement action through the truss robot arm.

2. Description of equipment:

The last step, use the truss robot to put the reinforce-bar on the shelf to finish the welding production. Using the truss robot to unload and stacking to complete the shelf. Monthly output reaches 25,000pcs.

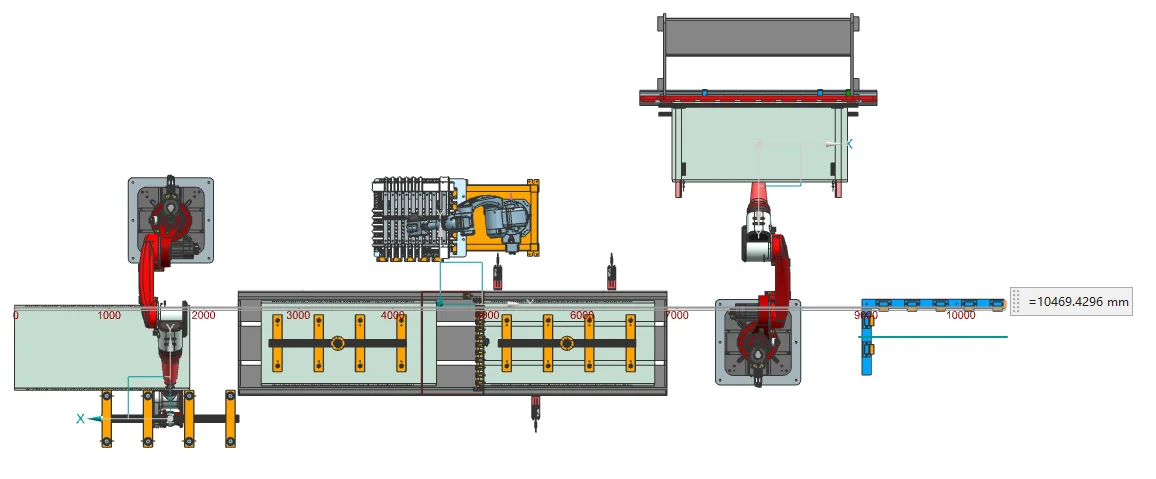

3. UN2200hbzhscx Shelf production line configuration

Specifications | Shelf Automatic production line |

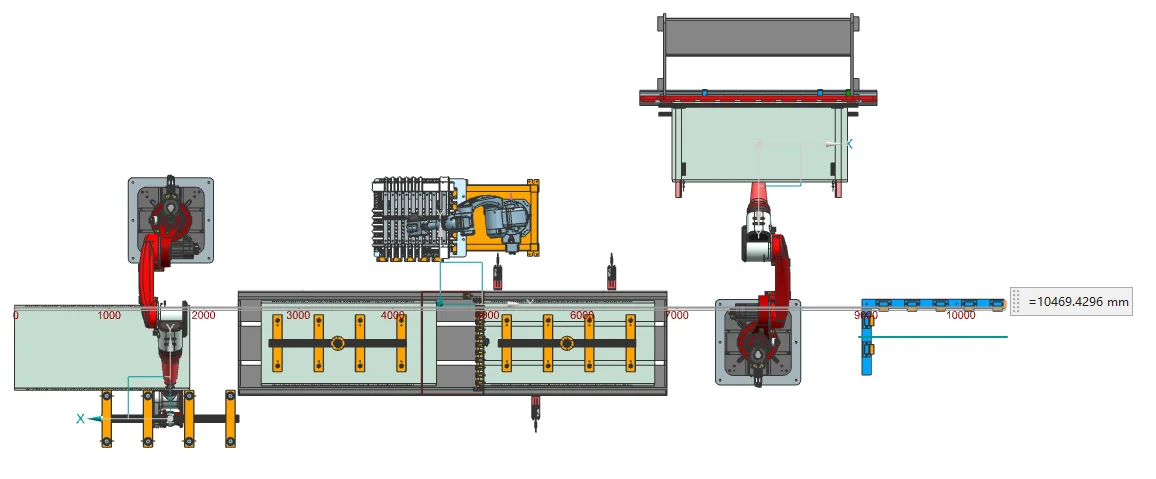

Size of equipment | L14 m * W4 m * H3.5 m |

Technological process | Uncoiler→Leveling→Two ends bend→Two sides bend→Rowing welding machine→Truss robot finished and Storage |

Worktable production line-height of equipment: | Apart from the ground 900 ± 50mm |

Material Scope | Material is Q235, stainless steel roll, and other flexible sheet metal |

Thickness: | 0.5-1.2mm |

Capacitance: | About 60KVA(380V,50HZ) |

Barometric Pressure | 0.5-0.6Mpa |

Product Range | Comply with the product drawing requirements confirmed by both parties/ Required by Customer |

Machining accuracy | Processing accuracy: the ultimate deviation accuracy of the tolerance dimension on the drawing is GB1804-m. |

Metal sheet color | Red and black/ blue and white/Required by customer |

Bending speed | 0.5s |

CNC system | SYNTEC |

Operational software | UNZ10 (Free update) |

Main accessories brand | |

Robot brand and model | Truss robot or Borunte robot |

Original pneumatic unit and air cylinder | AIRTAC or SMC |

Vacuum generator, suction cups | SMC |

Ball-bearing and linear guideway | HIWIN |

Axle bearing | NSK |

Reduction gearbox | ZD(Zhongda) |

Programmable control unit(PCU) | SYNTEC (Chinese operation) |

Inverter | SYNTEC |

Low voltage appliances, buttons, indicator lights, air switches | Schneider |

Intermediate relay | Schneider |

Sensor | Panasonnic |

AC contactor | Schneider |

Servo motor | SYNTEC |

Wire and cable | Delrou |

SUPPLY ABILITY AND TRADING TERMS

Terms of payment

-T/T, 10% deposit before design the drawing draft, 60% before production, 20% before loading, 10% the balance after the adjustment and installation.

Lead-time

1.Design picture draft: 2 weeks

2.Production line: 3 months

3.Technical training: 1 week. The company can also provide in-door installation, equipment debugging, technical training services, to guide the plant establishment and production.

APPLICATION

Company / Factory / Storage / Workshop/ Production Department/ Manufacturing shop

| Product Style: Minimalism |

| Reference Price: $500000 -- $1500000 |

| MOQ: 1set |

| Brand: CBNT/ODM/OEM |

4

沪公网安备31010402003309号

沪公网安备31010402003309号